Is Your HACCP Plan Actually Protecting Your Customers?

April 6, 2025 | Safety Simplified

The production line is running hot. Pallets are stacking, alarms are chiming, and shift supervisors are fielding breakdowns while trying to stay on schedule. A pallet of reworked product comes from the line right before shift changeover and gets placed near the line temporarily before it goes on hold pending Aerobic Plate Count and coliform testing. Maybe the tag fell off or maybe they ran out on the floor, but the tag is missing.

The batch changes over, and a production worker comes across the pallet. They don’t see a red tag, assume it’s from the new (non-reworked) batch, and move the unvalidated product straight to the fill line. No one catches the mistake. The reworked product is now lost in the lot and released to the customer.

Three days later, results come in positive for Enterobacteriaceae, and so do the customer complaints—illness, strange odors, textural problems, and swelling packages. A hold is issued on the entire lot. The investigation starts. Your Hazard Analysis and Critical Control Point plan passed your last audit. You’re compliant on paper. But one oversight—one tag, one rushed decision—just triggered a full-blown incident that could permanently damage your brand.

This doesn’t happen because people are careless. It happens because the reality of high-volume production rarely looks like the process flow diagram in your HACCP binder.

Where Are the Risks Hiding?

Material Mix-Ups

Is your rework, WIP, and raw material handling traceable in real time through your ERP software? Or are visual cues and verbal confirmations still doing the heavy lifting?

Temperature Controls

Are cold zones verified using calibrated thermometers, or are you relying on digital displays that might mask core temperature drift? Cold chain failures are a leading contributor to microbial growth in CPG products.[1]

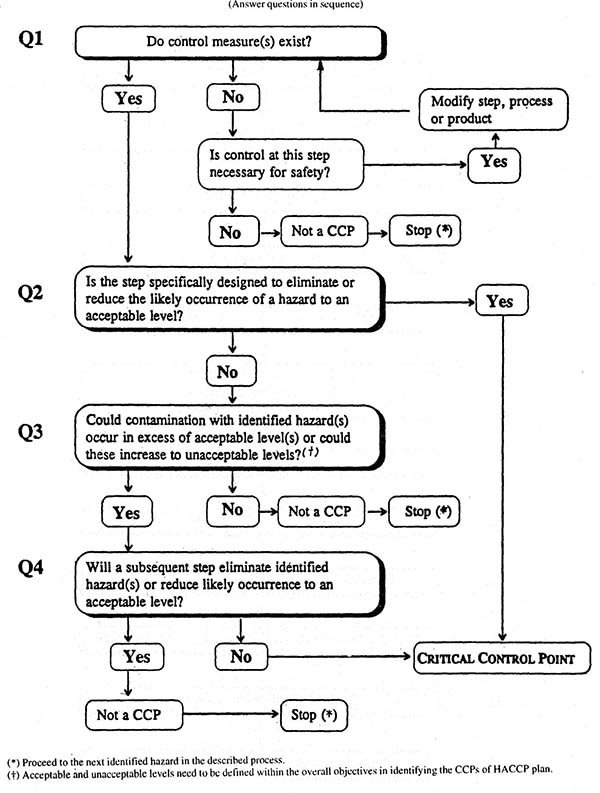

CCP Monitoring Under Pressure

Are metal detectors and other CCP validations tested under real production conditions? Or only when the line is slowed down and everything’s perfect? HACCP isn’t just about what happens on paper—it has to reflect the real environment where speed, heat, and chaos collide.

Pre-Op Shortcuts

Are sanitation crews hitting the hard-to-reach places—gaskets, valves, conveyor undersides—or just cleaning what’s visible before QA signs off? Are you validating with ATP swabs and aerobic plate counts, or assuming that “no debris” means “clean”? [2]

Training Retention

Are front-line operators trained to understand why controls exist? Or do they just know “don’t touch it if it has a red tag”? Was the forklift driver shown how to check system holds, or just told to avoid certain racks? Was QA confident the SOP made sense, or did they verify comprehension with production?

Most food safety failures look like operator errors. But they’re usually training failures—gaps in communication, retention, or accountability.

If your team doesn’t see CCPs, tags, and SOPs as shared responsibility, your HACCP plan is a liability waiting to happen.

The Cost of Inaction

A single breakdown in your CCP system can mean:

- Illness or injury to immunodeficient or vulnerable consumers

- Product recalls, regulatory action, and investigations

- Lost production time and profit

- Loss of contracts with retailers, co-manufacturers, or distributors

- Long-term brand damage—something even the best QA binder can’t undo

Your HACCP plan must work when the line is short-staffed, the operator is rushed, and the deviation is subtle. Customers aren’t protected by your audit trail—they’re protected by the daily decisions your team makes under stress.

So ask yourself honestly:

Is your plant compliant on paper—or is it truly food safe?

References

- Montville, Thomas J., Karl R. Matthews, and Kalmia E. Kniel. Food Microbiology: An Introduction. 3rd ed. Washington, D.C.: ASM Press, 2012.

- Damodaran, Srinivasan, Kirk L. Parkin, and Owen R. Fennema. Fennema’s Food Chemistry. 4th ed. Boca Raton: CRC Press, 2017.